Mechanical Diaphragm Motor-Driven Dosing Pumps

The FGM series includes mechanical diaphragm motor-driven dosing pumps designed for high-performance chemical dosing applications.

Engineered and manufactured in Italy, FGM pumps combine robust mechanical construction, dosing accuracy, and long-term reliability, making them suitable for continuous-duty industrial processes and water treatment systems.

FGM dosing pumps are developed to operate reliably in environments where precision, durability, and operational stability are essential.

Thanks to their mechanical diaphragm technology, they ensure consistent dosing even under variable pressure conditions, while minimizing maintenance requirements and downtime.

Typical application areas include:

Industrial water treatment

Chemical processing plants

Beverage and food industry

Dosing of light polyelectrolytes

Process and utility systems

The FGM series covers a wide range of dosing requirements, from medium to high flow rates, allowing engineers and system integrators to select the most suitable configuration for their application.

Key performance characteristics:

Flow rates up to 2000 l/h

Operating pressure up to 16 bar

Multiple diaphragm sizes available to optimize dosing accuracy

Stable and repeatable dosing performance

This flexibility makes the FGM series ideal for both standard installations and customized systems.

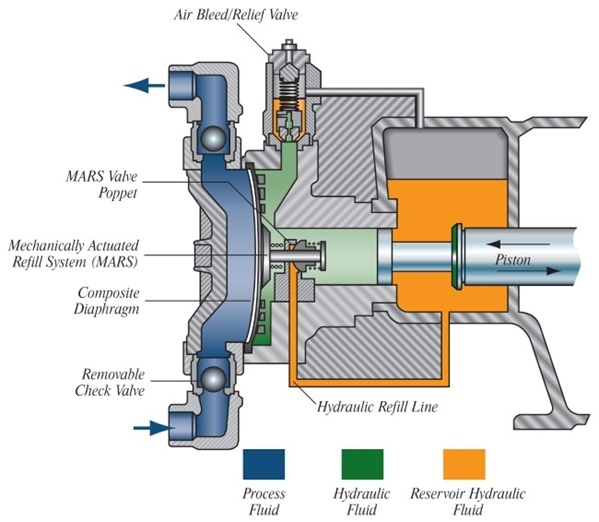

At the core of the FGM series is a mechanical diaphragm dosing system, designed to deliver precise and repeatable chemical injection while ensuring a physical separation between the pumped fluid and the drive mechanism.

Main benefits:

High chemical compatibility

Enhanced operational safety

Reduced risk of leakage

Long service life under continuous operation

FGM pumps are built using carefully selected materials to ensure resistance to chemical aggression and mechanical stress.

Depending on the configuration, the gearbox housing is available in technopolymer or aluminum, offering the right balance between corrosion resistance and structural strength.

Each component is manufactured and assembled following FG Pumps’ internal quality procedures, ensuring consistent performance across the entire product range.

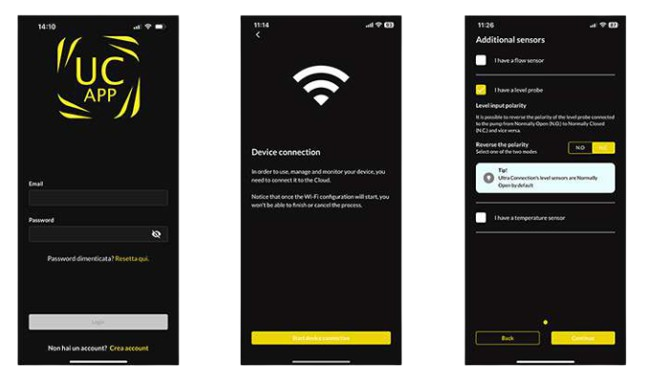

Selected FGM models are available with Wi-Fi connectivity, allowing remote monitoring and control via the Ultra Connection App.

This smart functionality enables operators to:

Monitor pump status in real time

Adjust operating parameters remotely

Improve system efficiency and process control

Digital connectivity makes the FGM series suitable for modern, automated dosing systems.

FGM dosing pumps are designed to integrate easily into new or existing systems.

Upon request, pumps can be supplied with additional safety and control components, allowing customization based on the specific requirements of the installation.

FG Pumps’ technical team supports customers in selecting the optimal configuration for each application.